Real-time Data From the Plant Floor to the CEO’s Office

The experts at ICAD can program your automation systems to gather plant data and generate concise, easy-to-read reports that provide real-time information for decision makers. ICAD designs industrial control systems to analyze and act upon a wealth of data every second. Decision makers can use this data to examine and improve the health and efficiency of processes.

Real-time Data Extraction

Real-time data extraction allows management to quickly see plant status and proactively act to improve productivity and efficiency.

The engineers at ICAD can design your industrial control system to record, analyze and report on a wide variety of meaningful parameters. Examples of real-time data that can be extracted include:

- OEE (Overall Equipment Effectiveness) can show productive time vs non-productive time. Increase visibility into your process by automatically logging the reasons for non-productive time.

- Hourly throughput of a process.

- Target vs actual values of a batch process.

- Key operating variables of machines throughout a plant to tell if they will require upcoming maintenance. For example, by tracking a motor’s amps, maintenance personnel can easily see if amps are trending upward, which may indicate that its bearings are going bad. By catching this early, the plant manager can easily schedule maintenance and avoid unexpected downtime.

Factory Data That Matters

Gain visibility into what’s happening on the plant floor.

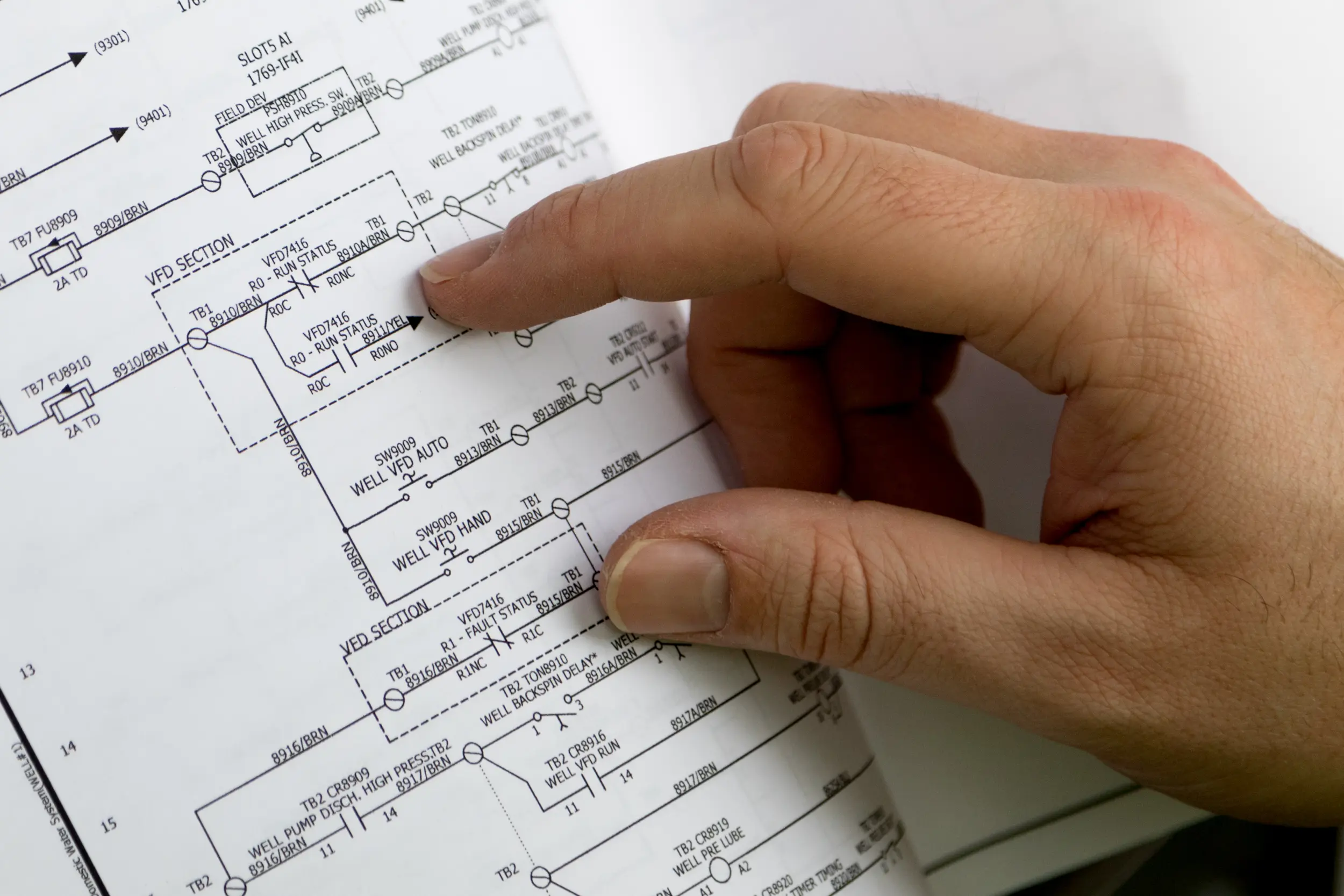

With our business intelligence reporting systems, you can reduce downtime while improving efficiency and production. Whether you need a SCADA (Supervisory Control and Data Acquisition) system, an MES (Manufacturing Execution System) system, or another way to gather complex information into actionable data, ICAD can combine the wealth of data from sensors, PLCs, and OEM factory floor machines into:

- A SCADA system or MES system which allows remote viewing of the real-time data from anywhere.

- Scheduled, triggered or on-demand pdf or excel reports which are automatically emailed to key decision makers throughout the organization.

- ERP (Enterprise Resource Planning) systems to further distribute and analyze the data in conjunction with corporate business systems.

Business Intelligence Software

ICAD has a keen understanding and deep experience in working with all major industrial automation software, including:

- Inductive Automation Ignition

- Wonderware:

- InTouch

- System Platform

- Dream Report

- Rockwell Automation:

- FactoryTalk View ME

- FactoryTalk View SE

- FactoryTalk Historian

- FactoryTalk Vantage Point

- GE iFix

- Sage ERP Solutions

- Oracle ERP Cloud Solutions

- Microsoft Dynamics ERP Solutions

- Seagull Scientific BarTender