Why ICAD Automation?

ICAD has been in the business of designing and implementing manufacturing SCADA in facilities for 20+ years. Our customers choose us because we combine our extensive experience with the latest proven technology and then tailor the whole package to each project’s custom requirements.

Our Design Process

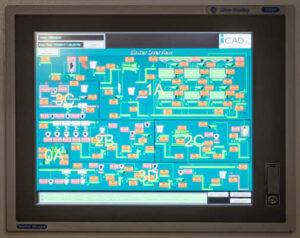

Manufacturing SCADA systems can display all the information from your facility in one single place.

Our role in these projects typically starts with the initial design of the manufacturing SCADA system long before ground is broken. During this time we coordinate heavily with OEM manufacturers of the individual pieces of assembly line equipment to ensure all of the inputs and outputs that they require are accounted for. We also consult with the customer, to develop a full design package including:

- Network diagrams

- IO & control panel drawings

- Controls narrative

- Sequence of operation

As typically happens with projects of such scale – we rely heavily upon our experienced engineers who knew exactly how each component worked due to specific customized client needs and unique business processes. Our seasoned engineers design intricate, yet easy-to-use systems including Rockwell Automation PLCs, Ignition and other suppliers like Eaton, Siemens and Schneider Electric.

Unlike many of our competitors, we can also provide in-house wet stamped professional engineering for the electrical infrastructure from the main service all the way to every individual motor. By providing the electrical design in addition to the manufacturing SCADA, our customers can count on us to be their one stop shop for everything electrical within the facility. We even handle all coordination with the electric utility company, which is typically a tedious and extended process that customers dread.

Manufacturing SCADA systems tie all of the machines in a factory together

Manufacturing SCADA Implementation

Implementation comes after we have completed the 100% design. We build and program all of our own control panels. Additionally, our sister company, Lighthouse Electrical is available to install both the electrical and automation infrastructure if the customer does not already have a preferred electrician. PLC’s, Motor Control Centers (MCC’s), SCADA systems and lot tracking–we integrate it all into one complete package.

Our customers appreciate that we handle both the design and build of the system. This eliminates the finger pointing and excessive change orders that can happen between engineers and contractors when they are from different companies. Our remarkable team is able to handle any electrical or automation project, no matter how intricate. From start-to-finish they ensure timely delivery and 100% accuracy at launch. These are the types of project our team enjoys that put our expertise to the test and create lasting client relationships.