Your company has a machine. This machine makes your company $4,000 per hour. Your job is to ensure that this machine stays running. This machine is 20 years old. This machine has 20-year-old parts that fail. Until recent supply chain issues, you could order next day parts and keep things going with minimal downtime. Now, with supply chain issues, these parts have 6+ month long lead times. Let’s do the math; $4,000/hr. downtime * 6 months = $a lot of money. How do you work within these parameters; where you must minimize downtime, but you cannot get parts due to long lead times? Here are some best practices.

Produce a plan

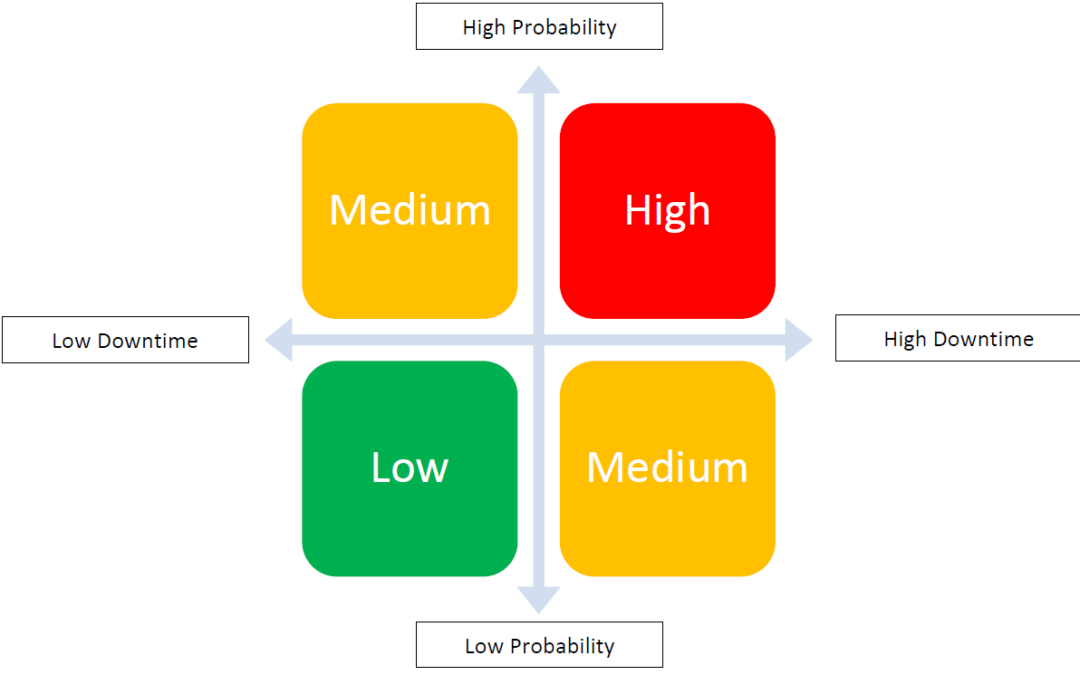

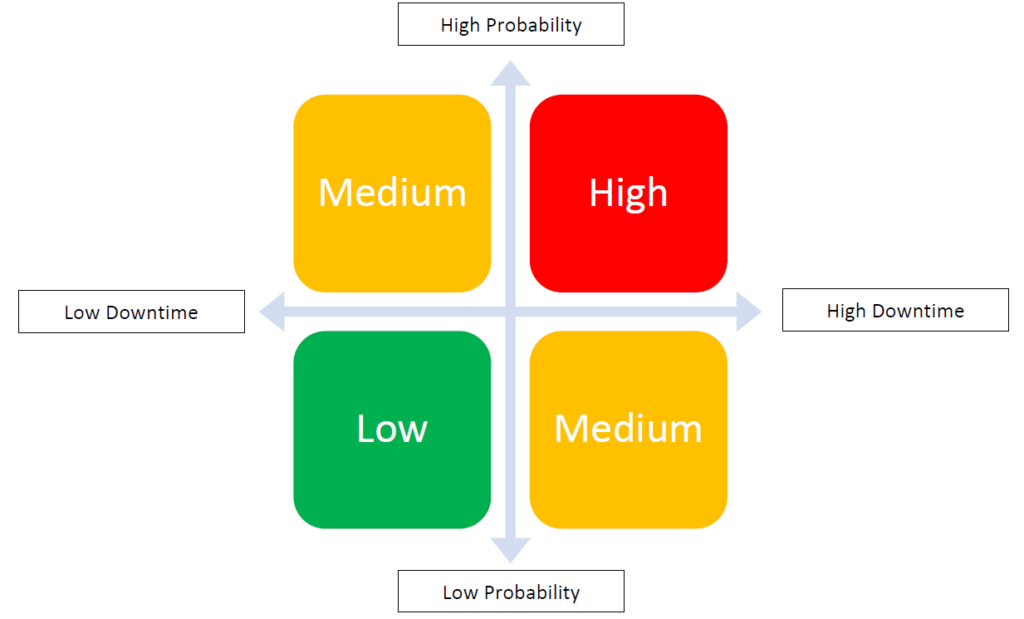

Probability and Downtime Risk Assessment Matrix

I know this sounds like a “duh” moment, but you would be surprised at how many maintenance departments have a plan of “just fix it when it breaks.” This is likely not you, because you found this article, but if it is you, make a plan.

Start by identifying (1) the different ways of failure and (2) the impact that each failure would have to downtime. If something has a high probability of failure and a high level of downtime, it needs to be addressed. If something has a low probability of failure and a low level of downtime, then you probably don’t need a spare. If something is high probability and low impact or low probability and high impact, then you are in a gray area and need to decide if it worth mitigating on a case-by-case basis.

Find spares

If something has a high probability of failure and a high level of impact, the first step of mitigation is to see if you can get spares. If you can, get some! Problem solved. Even if you must pay a premium over MSRP, it would still be wise to get essential spares. Paying $1,000 more than MSRP costs a lot less than $4,000/hr. downtime. Quick Tip: Manufacturers will sometimes prioritize rush items if they know it is needed urgently. For example, if you order one single part from Allen Bradley with overnight shipping, it will be flagged as a rush item in their system and be given priority over other orders.

What if I can’t find spares?

If spares are not available or if the lead time is so long that the part might as well be unavailable, you still have options. The first thing you can do is find used parts. Normally, I would not recommend this. Used parts carry the risk of not working. But in today’s age where new parts have a 6+ month lead time, you must take what you can get. The good news is that with the power of the internet, you can find virtually anything used online. Ebay, plchardware.com and Radwell are all places with a lot of automation parts.

If you do end up buying used parts for spares, do not skip the important step of testing them when you receive them. You could be buying a used part from the most reputable seller, but still have a dead-on-arrival condition. It is just the nature of buying used parts.

Other Options

If you are averse to used parts, you can also substitute with readily available parts. For some parts, this may be easy; terminal strips can usually fit in similar spaces on din rails, 3

VFD’s can usually be substituted with competitive brands.

0.5mm pushbuttons are interchangeable in the same hole and VFD’s can even be swapped between manufacturers. For other parts, such as PLC’s and HMI’s this may be difficult. Unfortunately, it is usually these not-easily-substituted parts that have the worst availability problems. If you have a PLC that has IO cards on backorder for 6+ months, you are usually left with the choice of used parts or changing out the whole thing. If the PLC in question is old and obsolete anyways, this makes a strong case for upgrading to something new.

PLC changeouts are a common thing performed by system integrators. One wise tip: find an integrator with experience both the PLC that you are removing and the PLC that you are installing. This will help to make sure nothing is missed during the program conversion.

Key Take-Aways

Even though lead times are long, it is still possible to keep your facility running with minimal downtime. For starters you need to identify the risks and the severity of their impacts. Then you need to work at producing contingency plans. It is always best to see if you can have new replacement parts on hand, but in today’s age of product shortages, used parts and substitutions.

If you need help deciding what the best strategy is for your equipment, give ICAD Automation a call. We have 25+ years performing risk assessments on multitudes of different automation equipment. We also have the knowledge of old (RE: obsolete) equipment, so that we can recommend the best migration path forward without missing any of the details that are missed by people not familiar with legacy equipment.